Figure 6 : Magnets on CD

6. Glue the CDs to the can

Now you can glue the CDs to the top and base of the can halves. Make sure each half remains vertical; use a ruler if you need to. You want the generator to be as upright as possible. It's not difficult to do, but it requires a little patience and a lot of hot glue.

Also, try to follow the examples in the photos. The Savonius turbine requires that the two can halves over lap a little. This makes the air "push" on both "buckets" at once. Clever, huh?

Figure 7 : Glued on and overlaps a little

7. Paper towel holder preparation

This is the opposite half of the "needle bearing" I wrote about before. You'll need to make this deep enough so that the generator stays in place, but not too deep or too narrow that friction becomes a major problem. Some suggestions:

- With a hammer, tap each end with a small blunt nail followed by a Phillips head screwdriver.

- Just make a deep dent, not a hole.

- Test the mechanical action frequently (with your turbine)

- Adjust the height of the nails if there's not enough (or too much) pressure on the generator (i.e. it keeps falling out or it's stuck and really slow)

Once satisfied, glue down the corks to the CD.

Figure 8 : Paper towel holder with dimples in

8. Wind the copper coils

This part is crucial. The amount of power you generate pretty much depends on two things: (1) The speed of the wind, and (2) number of coils. Other factors also play a role, but these are the big ones. You have no control over the wind though, so make this step count. I highly recommend using thinner gauge wire than I did. I used 28, and got decent results, but I think 36 gauge will blow the doors off of my current set up. It's all about the number of wraps. The 36 gauge stuff is harder to find, so you can make do with thicker stuff (just be aware of the cost of doing so).

Here's how to go about it.

- use a dowel for the big spool of wire

- put bobbin on an awl, then insert the awl into variable speed drill

- leave 10 - 15 cm hanging when you start. You'll need these to make connections later.

- wind the first wrap slowly or by hand. If you're using thin stuff, do it by hand.

- you can increase speed thereafter. Again, be gentle if you have the thin wire.

- go back and forth, try not to cross, be neat.

- if using thin wire, be careful:

- in case of breakage, use a lighter to burn off the enamel that insulates the wire

- tie the pieces back together tightly

- it doesn't hurt to check the repaired connection with multimeter

- once finished, tape down the coil.

- leave 10 - 15 cm on the outside, too

- burn off about 1 - 2 cm worth of the enamel and the end of each coil with a lighter (just be careful with thin stuff, since it will burn up really quickly--a quick pass with the flame should suffice). Use fine sandpaper to take off anything that stays on.

Figure 9 : Do the winding with a drill to speed things up

Figure 9 : Do the winding with a drill to speed things up

9. Label the coils

I know, this seems kind of dumb to get its own step, but it's reaaaaalllllly important. The next few steps evolve into tangles and chaos pretty quickly, so it pays to be organized here. You're going to make three groups of four: A (red), B (blue), and C (green). Using Avery circle labels can help a lot. I found the combo of letters and color made life easier.

P.S. (ignore the odd ordering of the "B" group in the photo. Just number them B1 through B4. I had the order the way you see it there because of a different--and less efficient--wiring method I had tried earlier. More on that later).

Figure 10 : If you don't do this you'll forget which is which!

Figure 10 : If you don't do this you'll forget which is which!

10. Solder the coils together

Here are some useful tips:

- solder flux helps a lot. You can use a lot less solder and with a lot less hassle.

- follow the diagram (bears repeating)

- do one group at a time. Start with A1 to A2, A2 to A3, A3 to A4, then go to the B group

- test the layout using the pattern provided.

- solder a thicker wire lead to the "1" end of each group. This will lead to the rectifier. More on that soon.

Figure 11 : Make sure this step is correct.

11. Make a base for the coils

I made my prototype out of foam core, but this will depend a lot on the size of your coils, the size of your magnets and the shape of the frame. Plus, if you're planning on keeping this outside instead of hooked up to an AC vent of whatever, keep weather proofing in mind (and while you're at it, give the Pringles can a good going over with Scotch Gard--I haven't tried it, but let me know what works for outdoor versions you make).

The most important thing is to try to get the coils to be as close to the magnets without collisions. If you can position the coils on the base so they sit just 1 mm below the spinning magnets (watch out for wobble) then you're in good shape. Also, try to make the base as stable as possible. At higher RPMs, the turbine can really start to rattle a bit, so keeping things together in those conditions is crucial.

Figure 12 : Excuse my handwriting

12. Layout of the coils

Once again, follow the picture. This is by far the most confusing part, and I think the picture should really help. Lay down one group (e.g. "A"), then another, then another.

Check that the current all flows one way. That is, if you imagine an electron running through the coils, it always enters the coil from one particular side and exits from another. Just don't cross the wires over, and you should be fine.

Now glue those coils down. Glue 'em down good.

Once that's set, solder the remaining three ends together (the ones not soldered to thick wire that should be sticking out of the "4" coils). This is the neutral point. In our circuit, you won't need to access this junction again, so you can tape it down or otherwise hide it under the coils' base, along with excess lengths of the other connections. In fact, the more you can do to tidy up stray wires, the better. A malfunctioning turbine that comes out of its divots has a nasty tendency to grab exposed wire and tear it up. Fun to watch, but hell to repair.

What you should have left are the three thicker wires connected to the "1" coils on each of the groups. This will lead into the AC to DC conversion circuit.

Figure 13 : All wired up

13. A brief explanation

Okay, so I haven't really gone over much in the way of what has been wired up here. What you have now is a Y circuit for a 3-phase alternating current generator. Instead of how we usually think of AC, like one big sine wave, this contraption has three waves working at three different phases at the same time.

The benefit of doing it this way is that we can jam in some more coils than we would if we just did a simpler version that produced a simple AC wave. Also, this method allows us to get about 1.7 times more voltage out of the generator than the coil groups would produce on their own. That's the magic of this "Y" configuration: it gets us more voltage for low RPM generators, which is definitely what we have here.

There is another configuration worth mentioning (and it's the reason my "B" looked out of order in the photos). The "Delta" configuration gives us the same voltage as the individual coil groups but about 1.7 times the current. So, if you really needed more current, and you could get the turbine spinning fast enough to take care of your voltage needs, that might be the way to go. It wasn't for me, but feel free to research it for your own stuff and let me know how it works for you.

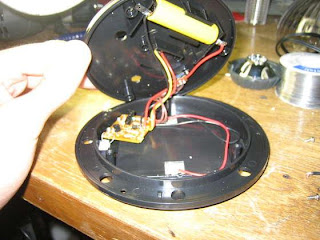

14. Circuitry

There is a diode rectifier circuit shown below. This should make a nice, neat converter for AC to DC that you can tuck away wherever you need to.

That being said, start with a solderless bread board.

Either way, the big schottky diodes will need headers or wire soldered to them to fit in. They have leads that are too wide to go in. Regular diodes will fit fine, but they have a higher voltage drop. If you use the diodes I mentioned in the parts list, you lose less voltage with these big guys. Since every volt counts here, I'd highly recommend you deal with the added trouble of the oversize diodes.

When you put the circuit together, follow the rectifier diagram, watching the diode bands and capacitor polarity. Switching things the wrong way will make the circuit not work (or worse.) Attach a multimeter to leads off both ends of the cap and be ready to watch the voltage (start in millivolts for a reading, then work up as you spin it faster).

Attach coil leads by color per the diagram--they go between two diodes. The template should make this pretty clear.

Figure 14 : Circuits

15. Time for the test!

No time like the present. Blow on it, put it in the wind, attach magnets to the vertical piece of the frame and tack it up on a AC vent, hit with a Shop Vac blower (I've done this--it holds up just fine).

Some tips:

*apply more WD-40 if needed (note: a helpful commenter let me know that WD-40 is not a lubricant, but a solvent that has similar properties--until it dries up. Use light weight oil instead, 5 to 10 weight)

*blowing on it will get you about .5 V DC with my set up. Hopefully you will get a lot more (it's those thin wire wraps that will do it for you)

*I had 1.12 volts with it sitting on a fairly gentle AC vent

*with the Shop Vac, it gets up to 6 V at least before it starts to rattle like crazy and pop out of the dimples. You will probably get even better results.

Figure 15 : Success, it works!

16. Conclusion

That's it! You have a crazy renewable energy source of perhaps dubious usefulness. BUT there is a lot more that can be done. I'd like to throw out a few suggestions to the crowd for thing to try:

- double up the magnets and coils. Put one set on the bottom and one on the top. Wire the DC output of each in serial and double the voltage. Hopefully.

- bigger, badder coils. Really see if you can up those wraps to a crazy degree. I think that's the key.

- try a different bearing. My big thing is to use as simple and readily available parts as I possibly could, so I swore off fancier parts. You have no such limitation. I have it on good authority that skateboard bearings would be great for this. Or some other kind of bushing. Let me know what you come up with (especially if it's hacky, cheap, and better than what I've done.)

- Small lazy susans are available at art and sculpture supply stores that might also make good bearings.

- Made a bunch of these turbines? What happens when you wire them together in series? Can you make a "Pleech" farm?

- There's another more efficient Vertical Axis Wind Turbine design called the Darrieus Turbine (http://en.wikipedia.org/wiki/Darrieus_wind_turbine). It uses lift instead of drag. If you have an easy way to modify this turbine into one of those, drop a comment down here.

What I'd really love is for this to be the first (well, second) version in a long series of continually improving small turbines, the goal of which would be to power small devices (phones, sensors, art projects installed on public buildings, etc.) So, what did I do wrong? And what could be done a whole lot better? If you have answers, let me know. Hopefully, we can "crowd source" a way to make a pretty decent, and fairly cheap, wind powered generator.